TIESSE ROBOT

Robot solutions for advanced welding

Tiesse Robot will be in Hall 13 – Stand C21 to present its most advanced solutions for the automation of welding and industrial handling processes. A concentrate of technology, reliability and flexibility designed to meet the needs of manufacturing companies that focus on innovation and productivity.

Tiesse Robot will be in Hall 13 – Stand C21 to present its most advanced solutions for the automation of welding and industrial handling processes. A concentrate of technology, reliability and flexibility designed to meet the needs of manufacturing companies that focus on innovation and productivity.

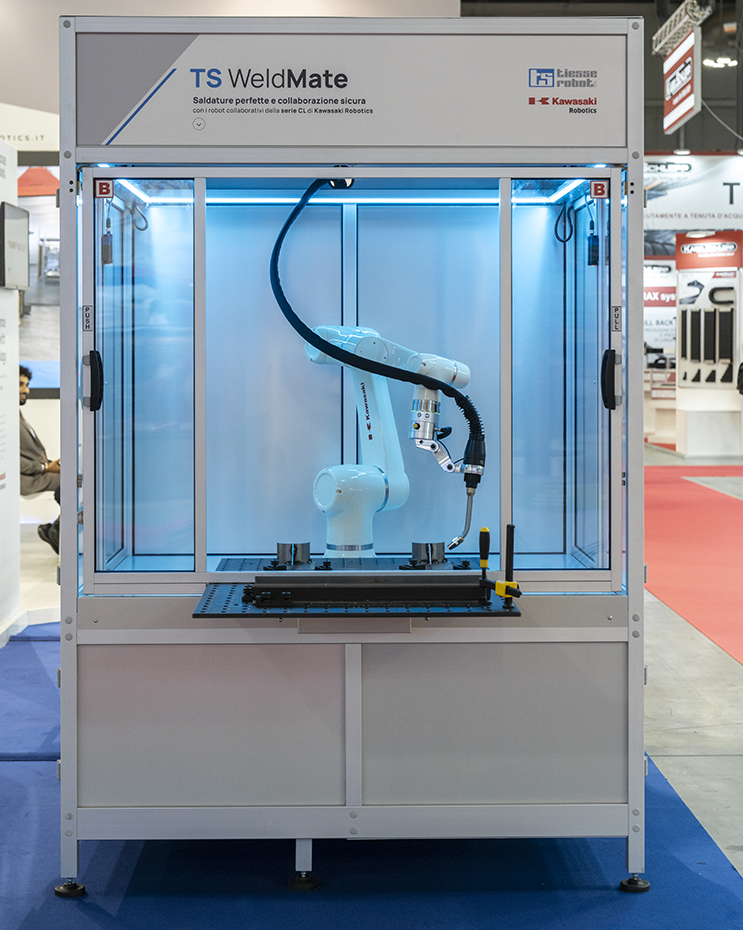

The star of the stand will be TS Weld Mate, a compact dual-station welding cell, mounted on a manual rotary table, with a CL110N collaborative robot. A flexible, safe solution that is also easy to integrate in shared production contexts, perfect for realities that wish to automate without sacrificing operational simplicity.

Also on show are three high-performance industrial robots, each designed to respond to specific production needs; two of these are being presented for the very first time.

BA013L, new preview model: arc welding robot with FRONIUS torch and wire feeder, payload of 13 kg and reach of 2,093 mm. The internal cable wrist optimises cable passage, ensuring greater precision, less wear and tear and easy maintenance.

RA020N: Kawasaki Robotics robot for laser welding with filler wire, with a payload of 20 kg and reach of 1,725 mm. It ensures high accuracy and repeatability even in the most complex machining operations.

MXP710L, new high-performance model, exclusive preview: heavy-duty handling robot with 710 kg payload and 2,930 mm maximum reach. An evolution of the MX series, with a more compact design, higher operating speeds and up to 21% shorter cycle times.

We look forward to seeing you at our stand to experience the efficiency and practicality of automation applied to welding.

![]()

![]()

![]()