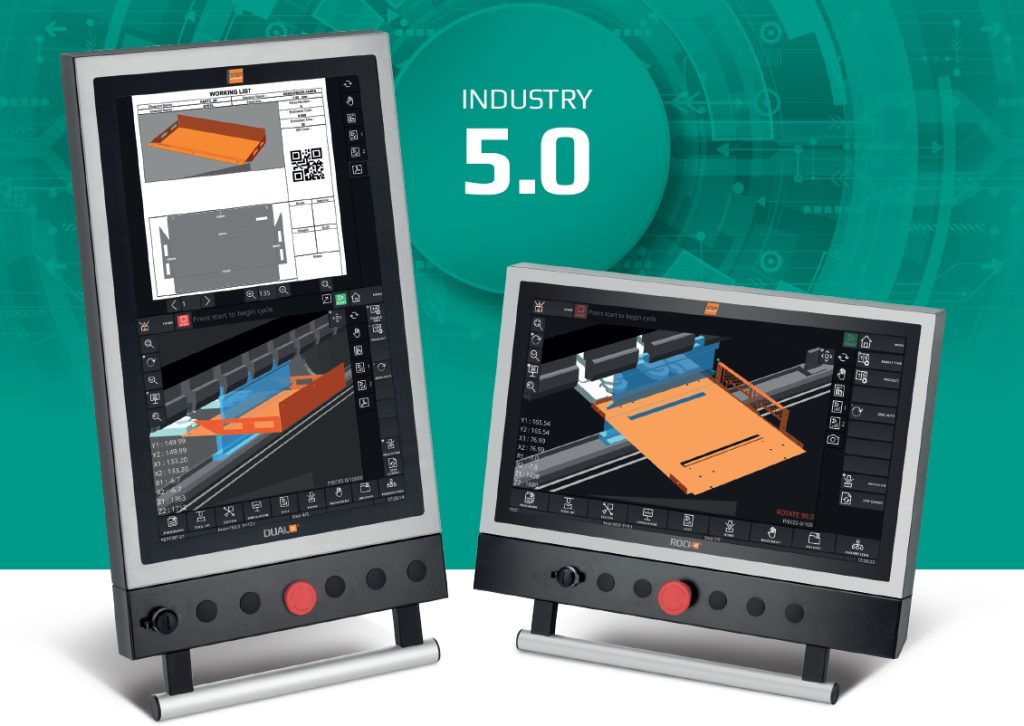

Founded in 2012, in a few years STEP Automation has been able to carve out its own space, both in the area nationally and internationally, where it has become a supplier of many manufacturers of bending systems. Recently the company is expanding its range of action thanks to the development of specific projects for the automation of folding machines and traditional hydraulic presses. STEP Automation proposes itself as a partner technology to develop specific and customized control systems e programming. At LAMIERA 2025 the company shows especially the new generation Dual NC series that offers a higher level of efficiency in programming and control for sheet metal machines. The versatility of a dual monitor virtual DUAL22 and DUAL27, the newest member of the family Rock, offers a dual virtual monitor that allows you to work with maximum efficiency, having them all information under control. Based on wide and robust capacitive display, with Full HD resolution, 4GB RAM memory and a state memory 128GB ultra-fast solid. Dual arises from the need to have an area of the screen to dedicate to activities auxiliary to bending through a double virtual monitor. This allows you to meet a need which has manifested itself in many applications through the adoption of a second monitor, typically placed above the main cnc, through a single cnc, of large dimensions, positioned vertically and consists of two functionally distinct graphic areas. In the second monitor area, you can view useful documents such as images, videos or Pdfs, which can be uploaded even from your mobile device, and visible and accessible during the production. What is traditionally used as a paper support (drawings of the piece, specific details of the tooling or production sequence) becomes multimedia content available on the upper screen. The operator can also choose the contents of the dual virtual monitor to suit your own needs and preferences. Thus, the traditional productive screen can be matched to the designs of the piece, or to photographic or video attachments. Or the definition of the sequence can be combined with the display of the equipment of the machine, so as to allow adoption of variations in progress, so fast and efficient. Also available the support of a WebCam, which can for example, resume handling of the back gauge, rather than the phase of bending. 5.0 ready Dual offers a package complete with functionality, from an Industry 4.0 and 5.0 perspective, for production management, real-time monitoring of the plant and energy saving strategies and monitoring . All stages of production are appropriately registered in a relational database, so as to constitute complete documentation it can also be used remotely and can be integrated in company management. Other functionality the organization is available of predictive maintenance, constituted from modules that any manufacturer can define and customize to manage al better the typical features of your system. Again with a view to 5.0, new technologies installed in the CN Dual allow to carry out a series of operations from remote such as technical assistance through dedicated software, machine status monitoring through cloud reporting and system integration into a smart factory, through support for the MTConnect industrial communication standard and IoT support through MQTT protocol. […]

DUAL NC series for bending applications