MARPOSS

Improving quality and increasing production efficiency

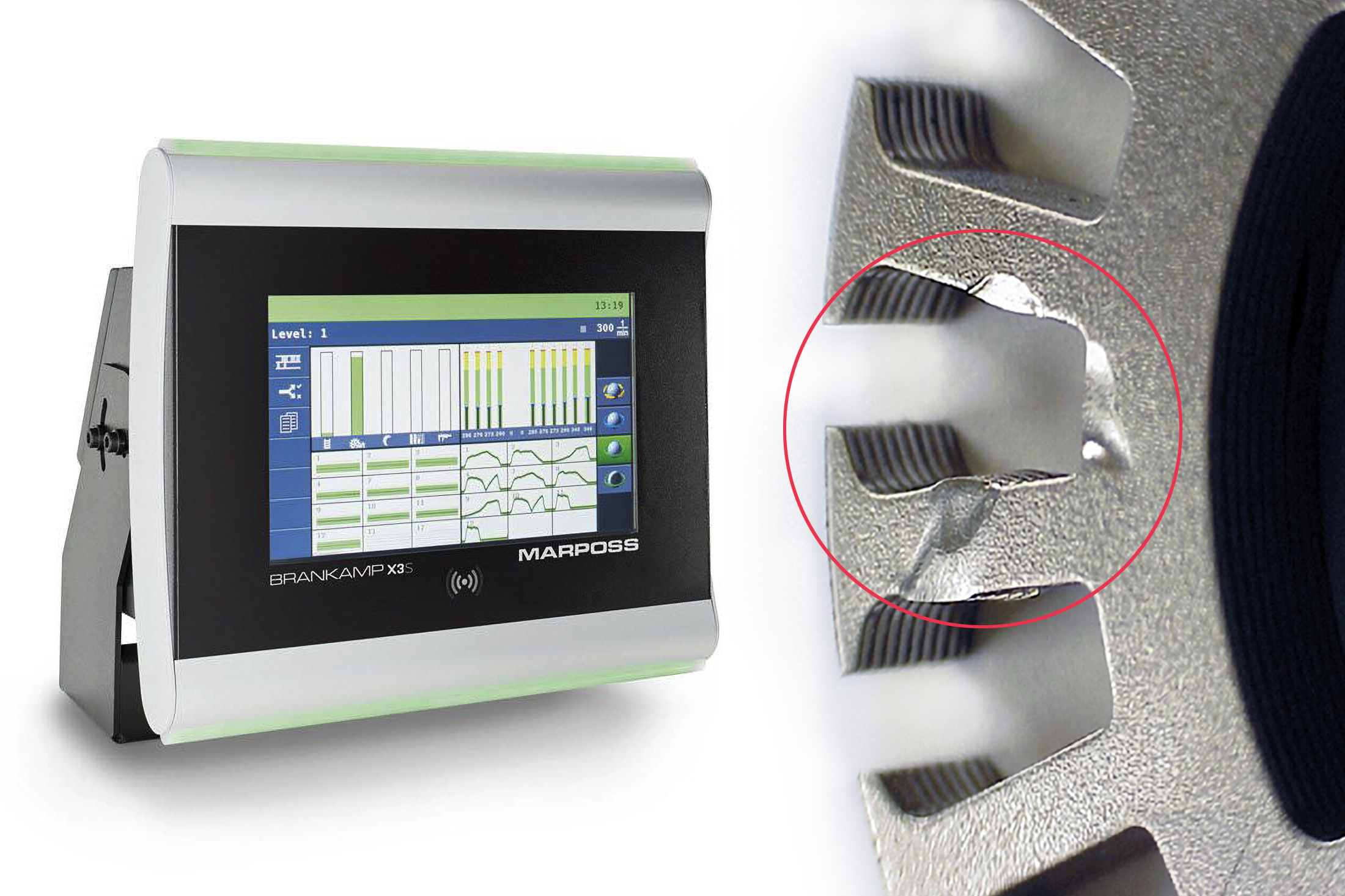

![]() The monitoring of sheet metal stamping is essential to guarantee the quality of the parts produced and prevent damage to the tools. One of the most critical problems in this process is, for example, the rising up of scrap and cuttings, which can dent the machined part, creating isolated defects or damaging the die itself. This phenomenon can generate scrap, reduce quality, increase the maintenance costs.

The monitoring of sheet metal stamping is essential to guarantee the quality of the parts produced and prevent damage to the tools. One of the most critical problems in this process is, for example, the rising up of scrap and cuttings, which can dent the machined part, creating isolated defects or damaging the die itself. This phenomenon can generate scrap, reduce quality, increase the maintenance costs.

With MARPOSS monitoring devices, the presence of abnormal scraps and cutouts can be detected at an early stage. Modern, easy-to-apply sensors and high-performance electronics enable the precise detection of off-cuts. In particular, thanks to the ultra-rapid response of the devices, an emergency stop can be triggered within just 4-5 milliseconds of first contact with the trim.

Such a quick stop often allows modern, slow large presses to be stopped before the moulding cycle reaches maximum force with the mould closed. This results in an even more significant reduction in breakage damage and contributes to mould preservation. The adoption of these solutions improves production efficiency, reduces maintenance costs and downtime, while guaranteeing a high quality of the finished product.

In view of Industry 4.0, MARPOSS monitoring devices can be integrated into the company network to transmit key production status data in real time, e.g. in the standard OPC UA format. Thanks to IoT connectivity, information on job progress, machine efficiency and process parameters can be collected and shared directly with management systems and analysis platforms. The interconnection with the company’s digital ecosystem enables predictive assessments and continuous optimisation: a concrete step towards transparent, real-time protected and efficiency-oriented production.

![]()

![]()